Date

- 2025 Apr 04

- Expired!

Time

- 09:00

Location

Presenter

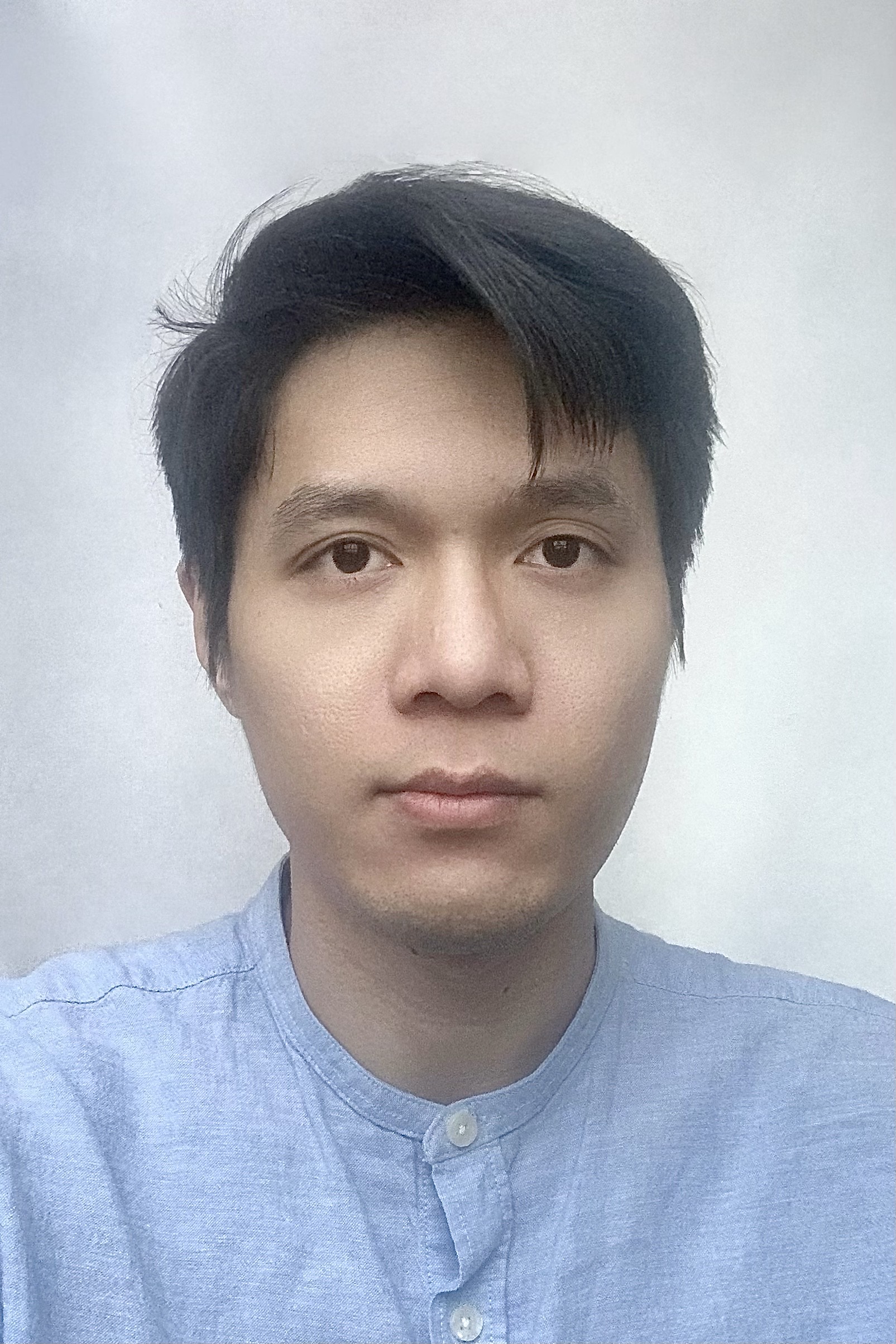

Van Minh Dinh

More Info

Defence of doctoral thesis: Van Minh Dinh – Valorization of biomass byproducts: the potential of chitin and lignin through solid catalysts

Umeå University | WWSC

The defense is taking place at Lilla Hörsalen, KB.E3.01, KBC-huset, Umeå University, Umeå, Sweden

Opponent: Assoc. Prof. Satu Ojala, University of Oulu, Oulu, Finland

Supervisor: Prof. Jyri-Pekka Mikkola, Umeå University

Abstract:

Chitin, commonly found in crustacean shells, can be deacetylated to produce chitosan, a versatile material with various industrial applications. Traditional chitosan production is energy-intensive and uses corrosive reagents. In order to improve the process, Paper I introduces a ‘greener’ method, using the ionic liquid [Emim][OAc] for chitin pretreatment, followed by microwaveassisted deacetylation in aqueous NaOH or [TBA][OH] solutions. The pretreatment effectively reduces the chitin crystallinity, improving its reactivity for achieving up to 85% deacetylation in 1-2 hours. Both [Emim][OAc] and [TBA][OH] are regenerated (97% and 83%, respectively), offering a more sustainable chitosan production method, which can serve as a substrate for e.g. catalysts in industry. Paper II investigates the adsorption and catalytic reduction of phenol red dye using Ag-loaded chitosan catalysts. These catalysts display excellent activity across a broad pH range (4–11), with efficient adsorption at near-neutral pH (6.4) and room temperature. After five recycling cycles, the catalysts maintain structural stability, with only a 0.2% loss of Ag, demonstrating their potential for wastewater treatment. Lignin, an abundant but underutilized polymer in wood biomass, is typically burned for heat. Recent interest has focused on converting lignin into valuable products like jet-fuel range hydrocarbons and fine chemicals. The challenge is selectively breaking C–O and C–C bonds in lignin while maintaining catalyst stability. Paper III explores C–O cleavage in lignin models using multifunctional Ru/NbOPO4/TiO2 catalysts, achieving high yields of hydrocarbons (86.9–100%) under mild conditions. Paper IV investigates both C–O and C–C cleavage with Ru/NbOPO4 catalysts, producing >99% conversion in model compounds with high yield of hydrocarbons. The catalysts’ performance is driven by the tunable synergy between Lewis and Brønsted acid sites of niobium phosphate and the hydrogen activation role of Ru. This interdisciplinary research advances biopolymer chemistry and catalysis, offering sustainable solutions for environmental and energy challenges by maximizing biomass byproducts and providing eco-friendly alternatives in wastewater treatment and renewable energy.

https://www.diva-portal.org/smash/get/diva2:1943288/SPIKBLAD02.pdf