This article is part of a news series where we highlight the latest research from our Treesearch partners and within the Treesearch thematic research areas. Articles are published regularly once a month.

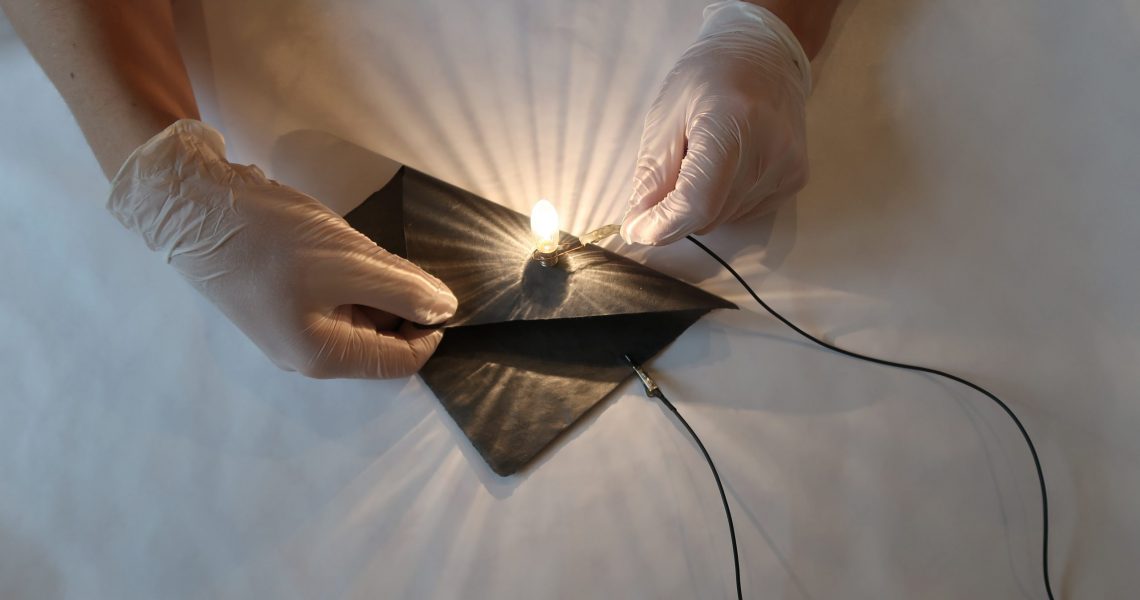

The presented study explores the mixture of common cellulosic pulp fibers with conducting nanographite flakes from 2Dfab, a high-performance electroactive material. The resulting nanographite-filled paper shows well-performing electrical conductivity while at the same time demonstrating the mechanical characteristics of ordinary paper. According to the authors, this paper could easily be produced on a large-scale using water-based standard paper making methods.

Patrik Isacsson, main author of this paper and industrial PhD student at Ahlstrom-Munksjö and Linköping University, sees a lot of potential in the wide-ranging application of nanographite-filled paper.

We are trying to understand where the properties of this paper could be utilized best. Printed electronics is one example as we showed in this work where you can use it as a printed substrate and electronic components. But it has also shown some interesting electrocatalytic properties. So, we are currently investigating it for electrolytic production of hydrogen peroxide. One could also imagine that it could be used as a conducting scaffold into which we load electroactive materials so it can be used in batteries. Maybe it is even suitable as a backplane for solar cells. I think there are a lot of applications to be investigated.

Patrik also points out the benefits of collaboration when conducting research:

As this research is truly transdisciplinary, it has been very rewarding to have such a broad collaboration in this project. Combining expertise on printed electronics at Linköping university and Rise Digital Systems with the extensive knowledge and know-how in papermaking at Rise Bioeconomy and Ahlstrom-Munksjö has been essential to the success of this work.

Against this backdrop, there is a wide variety of possible directions to continue research on nanographite-filled paper and further explore this material’s concept. While the nanocarbon used in this study is made from mineral graphite, research has shown that this kind of material can also be made by carbonizing biomass, like wood for example. Even though this carbonization process is not feasible on an industrial scale today, the material concept opens for the possibility of creating electronics entirely made from biomass in the future.

Patrik Isacsson, Xin Wang, Andreas Fall, Desalegn Mengistie, Emilie Calvie, Hjalmar Granberg, Göran Gustafsson, Magnus Berggren, and Isak Engquist (2020): Highly Conducting Nanographite-Filled Paper Fabricated via Standard Papermaking Techniques. ACS Applied Materials & Interfaces 2020 12 (43), 48828-48835

https://doi.org/10.1021/acsami.0c13086