4D characterisation of paperboard mechanics

The project involves the development of new experimental methods to characterize deformation processes in fiber-based materials, in particular paperboard. The experiments are to be performed on several scales, from micro to macro, and aim to increase understanding of the mechanisms that control the mechanical properties and behaviour of the material. Experimental devices that can be […]

Adsorption av funktionella polymerer tillcellulosa i blekningssteget – ett sätt att utöka fibrernas egenskaper

The purpose of this proposed project is to suggest new pathways for the adsorption reactions to cellulose fibers in the bleaching step in the kraft pulp process. The long-term aim is to develop a flexible knowledge platform that can be used for designing functionalized surfaces of the cellulose fibers in the bleaching step, using by […]

Production of new high-performance CNF biocomposites (Cellulose nano-composites)

The aim is to develop new methods for large-scale melt processing of thermoplastic composites reinforced with high content of cellulose nano-fibrils. The goal is a thermoplastic process capable of mixing and shaping thermoplastic compositions reinforced with 30 % or more nano-cellulose, obtaining a functional composite stiffness at least 10 times of the polymer matrix. Alternatively, […]

Processing & Mechanics – Bio-based Polymer Composite Materials

With this project, we aim to advance the understanding, synthesis, manufacturing and modelling of biocomposites. In particular, we target polymers reinforced with cellulose fibers that have been grafted with cellulose nano crystals, the wood-based cellulose fibers and nano crystals are an important resource from the Swedish forest industry. The idea is to scale up a […]

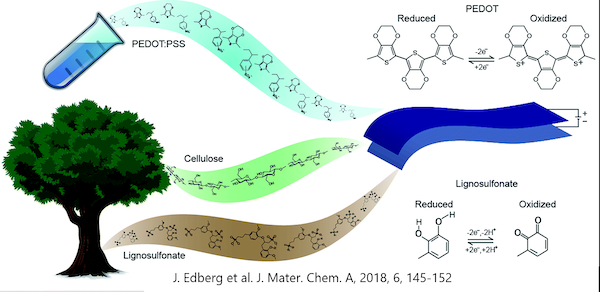

Lignosulfonate composited with electronic polymers for large scale energy storage applications

A renewable resource from existing forest industry is the black liquor that mainly goes to combustion. The dominating biopolymer in black liquor is a derivative of lignin. At LiU we have shown how lignin and lignosulfonate (LS) can be used to store charge into biopolymer electrodes, and built supercapacitors/supercabatteries of such electrodes. In these electrodes, […]

Karakterisering och kvantifiering av deformations- och skademekanismer i kartong under komplexa belastningsfall

Projektets mål är karakterisering och kvantifiering av deformations- och skademekanismer i kartong under komplexa belastningsfall. Sådana är praktiskta viktiga vid konvertering av kartong i allmänhet, men speciellt betydelsefulla vid 3D-formning av geometriskt avancerade strukturer. För att nå målet ska experimentella 4D datortomografiundersökningar kombineras med matematisk modellering.

Porous, optical and IR-absorbing cellulose for solar evaporators

This project aims at investigating how conducting polymers interact with forest-based materials to form hierarchically nanostructured aerogels. We will develop protocols for fine tuning the structural and mechanical properties of cellulose-base conducting aerogels, and to control the penetration of solar absorbers (i.e. conducting polymers) in the nanostructured forest-based aerogels. We will study how energy is […]

Fundamental understanding of the moisture uptake in modified wood

The use of wood and wood based materials in moist environments is limited because of these material’s susceptibility to decay fungi. The durability thus needs to be improved, which can be achieved by chemical wood modification. The exact mechanisms behind the increased durability of modified wood is however not known, but the lowered moisture content is […]

MODUWOOD – Modified durable wood products

Modern methods to protect wood from degradation aims at increasing the service life of the material by removing or reducing the cause of degradation: water within the material. This can be done by wood modification, e.g. acetylation or heat treatment. However, there is a lack of understanding of what happens within the wood, which hampers […]

New bio-based packaging and engineering plastics

The project is focused on the chemical design and development of new monomeric building blocks from lignin and cellulose feedstocks. These building blocks mainly include different cyclic diols, diesters, diamines, etc, to prepare mechanically rigid and thermally stable bio-based thermoplastics for use as high-performance packaging and engineering plastics.

Fouling and cleaning of membrane processes in ligno-cellulosic biorefineries

Reduction of fouling and efficient cleaning is of great importance for membrane processes to be successfully implemented in ligno-cellulosic biorefineries on an industrial scale. The key objective of this project is to develop real time methods to analyse fouling and cleaning plus new cleaning methods, e.g. enzymatic cleaning. Thus, the project aims to reduce water consumption, […]

Constitutive modeling for macro-micro delamination for paperboard/Tow ards zero defects in packaging technology

The project aims to develop experimental methods for characterizing packaging materials. In the project, the microstructure of packaging materials w ill be methodically characterized and linked to mechanical properties. Traditionally, mechanical testing of paperboard material has been carried out without regard to micro-level mechanisms. With new experimental methods such as in situ x-ray tomography, much […]