EPIC – elektro- och fotokatalys inducerat i papper

Den vanligaste metoden att framställa papper görs genom den så kallade Kraft-processen. I denna process tas olika komponenter bort från träet för att möjliggöra vidare framställning av högkvalitativ cellulosa och papper. En viktig del i Kraft-processen är den så kallade avlignifieringen. Under denna process öppnas cellulosaväggen och porer av storleken från 20 till 50 nanometer […]

Transparenta, cellulosabaserade förpackningsmaterial med goda barriäregenskaper

I mark och hav ansamlas på grund av mänsklig aktivitet stora mängder plaster, ofta från påsaroch förpackningar. I värsta fall tar det flera hundra år för naturen att bryta ner dessa plaster.För att åtgärda denna miljöförstöring räcker det alltså inte bara att vi blir bättre på att återvinnaoch slänga vårt plastskräp på rätt sätt, utan […]

Injection moulded polymers – imaging of composites with x-ray techniques

Investigation of the structure induced by processing of traditional polymers for packaging application (such as LDPE or HDPE) as well as new cellulose and ligno-cellulose based materials. Characterization include SAXS/WAXS imaging, birefringence, STXM, and CT.

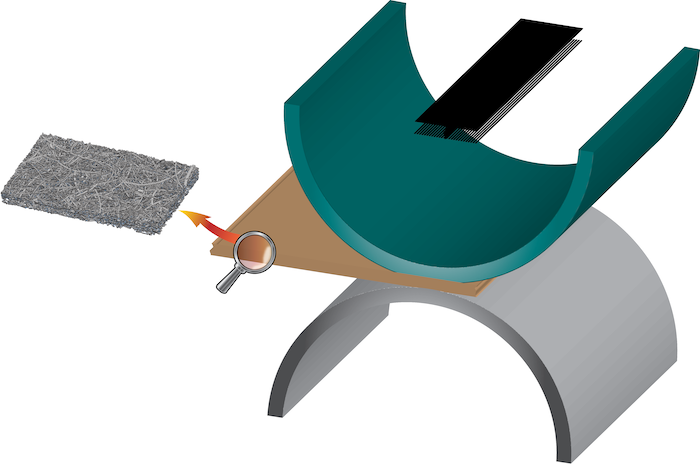

The effect of compaction parameters on the properties of high-deformable paper

This project addresses the challenges of producing high-deformable paper for 3D forming applications using the in-plane compaction process. Enabling 3D forming of advanced paper structures paves the way for complete elimination of plastic based packaging or partial replacement of plastic in multi-material packages, which aligns with current international strategies for a sustainable development of the […]

4D characterisation of paperboard mechanics

The project involves the development of new experimental methods to characterize deformation processes in fiber-based materials, in particular paperboard. The experiments are to be performed on several scales, from micro to macro, and aim to increase understanding of the mechanisms that control the mechanical properties and behaviour of the material. Experimental devices that can be […]

Adsorption av funktionella polymerer tillcellulosa i blekningssteget – ett sätt att utöka fibrernas egenskaper

The purpose of this proposed project is to suggest new pathways for the adsorption reactions to cellulose fibers in the bleaching step in the kraft pulp process. The long-term aim is to develop a flexible knowledge platform that can be used for designing functionalized surfaces of the cellulose fibers in the bleaching step, using by […]

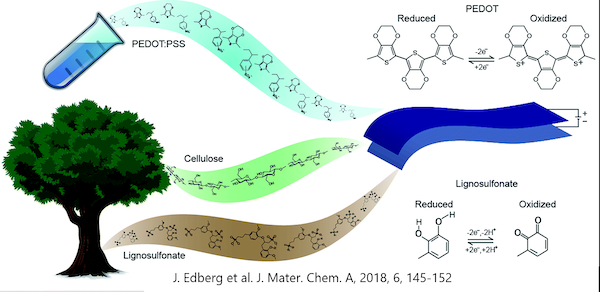

Lignosulfonate composited with electronic polymers for large scale energy storage applications

A renewable resource from existing forest industry is the black liquor that mainly goes to combustion. The dominating biopolymer in black liquor is a derivative of lignin. At LiU we have shown how lignin and lignosulfonate (LS) can be used to store charge into biopolymer electrodes, and built supercapacitors/supercabatteries of such electrodes. In these electrodes, […]

Constitutive modeling for macro-micro delamination for paperboard/Tow ards zero defects in packaging technology

The project aims to develop experimental methods for characterizing packaging materials. In the project, the microstructure of packaging materials w ill be methodically characterized and linked to mechanical properties. Traditionally, mechanical testing of paperboard material has been carried out without regard to micro-level mechanisms. With new experimental methods such as in situ x-ray tomography, much […]

Impact of compaction parameters on the mechanical properties of highly extensible paper

The possibility of producing three-dimensional advanced paper structures create the conditions for replacing plastic-based solutions or plastic details in packaging with multi-material and contributes in an essential way to strategies for a sustainable social development . Within this context, the project deals with the challenge of producing highly stretchable paper for 3D forming applications through in-plane […]

Process-adapted biobased assortments through novel development of the steam explosion process

The aim of the project is to, from softwood bark, develop and provide semi-manufactured industrial commodities with the following properties: a) Low content of process-disturbing/inhibitory substances during steam pretreatment b) Enhanced enzymatic digestibility c) High density and manageable properties for storage and transport Project partners: Swedish University of Agricultural Sciences, Valmet, Bio4Energy

Biocomposites-Materials modification to increase the processabilty at high fiber content

The current application aims at facilitating a substantial increase in the content of renewable lignocellulosic fibers in fiber reinforced wood fiber polymer composites (WFPL). The target is to enable production of WFPL’s with a fiber content >> 60%. For the forest based industries, this will create new market segments within construction, automotive and industrial goods, […]

Green wood adhesives based on side-streams from the pulp industry

In this project we propose to explore the use of side-streams originating from the pulp industry as adhesive binders for wood-based materials. The proposed project, aiming at developing novel, formaldehyde-free, adhesives from renewable resources, brings together experts in polymer/adhesive/wood chemistry with experts on forest/wood products and has the ability to gain novel, fundamental knowledge while […]